Mr. Jones, Chairman

Mr. Holroyd, Treasurer

Mr. Coombes, Secretary

Mr. Duckering

Mr. Jones [Chairman] leafed through the notebook and accepted the minutes of the last meeting, introduced Mr. Duckering and the meeting was brought to order,

Mr. Holroyd expressed his interest in Road Signs and proposed a special mention to Mr. Jeremy Tankard, who he believed was largely responsible for the typeface used on British number plates before they went all to shit and allowed any old crap typeface to define the letters. But this is clearly not the case as Mr. Tankard is no’but a lad, graduating, as he did, in short trousers, from the Royal College of Art in 1992 and The Great British Number Plate coming about in 1903.

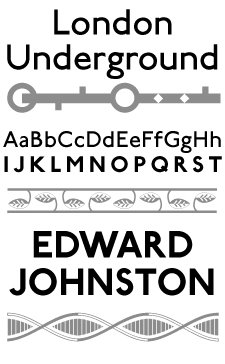

Edward Johnston, now there was a designer, he designed the famous London Underground typeface.

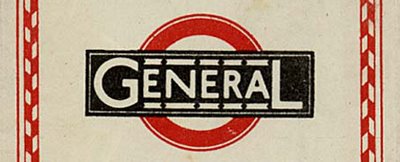

He also clarified the London Underground logo

after its corruption from the General Omnibus logo when the Underground group bought the London General Omnibus Company in 1912.

However the main item on the agenda was Mr. Holroyd’s passion for vacuuming in general and Charles Dyson in particular. This may seem like an opportunity to go into the Life and Times of Mr. Dyson, but as he has done little to further the cause of typography, or tunneling, we shall have to pass on that one. Suffice it to say Mr. Holroyd was interested in challenging the patents on the cyclone system, which is so central to the operation of Mr. Dyson's Hoovers, with a view to patenting his own wind-up clockwork beer-mat vacuum cleaner for use in the Immerging World.

At this juncture Mr. Jones [Chairman] pointed out that the best van he ever saw was in Batley.

There was a brief pause [which in some of the cheaper Westerns would be denoted by sage brush blowing down an empty High Street] and the meeting moved swiftly on.

After a particularly smutty and unbecoming comment from Mr. Coombes, Mr. Jones [Chairman] proposed creating another website, that could be used for fun and profit.

Following a train of thought known only to himself, Mr. Holroyd pointed out that the famous climber and mountaineer Michael Schumacher, is also quite a good racing driver.

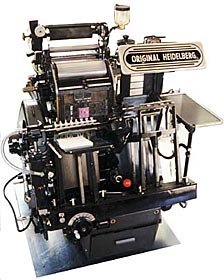

Mr. Duckering replied that they had a platen printing press in Trumpton, thereby confirming two things: 1. he's on the same wavelength as Mr. Holroyd and: 2. he's an ideal member of the Holmfirth Typographical Society. He went on to remark that said printer printed the poster:

DON’T FORGET

THE BAND CONCERT

AT 3 O’CLOCK.

THE BAND CONCERT

AT 3 O’CLOCK.

But as the print rate was about one poster an hour most people probably missed the band concert. Whether Michael Schumacher uses a Dyson vacuum cleaner was not established.

As the meeting moved into its Twiglet phase the matter of Internet Chairs was brought up – after Mr. Jones [Chairman] pointed out that internet suits were available that enabled you to enjoy the murkier pleasures of the World Wide Web [see Mr. Jones’ Other Website] in a more intimate fashion. It was proposed that the Society look into developing Internet Chairs to help online customers experience their bank balances at a more fundamental level.

The Treasurer’s Report failed to materialize for the third week and certain members of the Society are beginning to doubt the commitment of the Treasurer.

Mr. Holroyd did however, proposed another excellent money-making venture for the Society, which didn’t involve either Charles Dyson or vacuum cleaners. He pointed out that some lesbian acquaintances of his were making a fine living by washing their nether garments in the local launderette, collecting the detritus from the filter in the drier and selling it as Lesbian Fanny Fluff for a 100 notes a bag on EBay. Readers wishing to purchase this kind of thing should go to Mr. Jones’ OTHER website.